|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

workshop of led display manufacturer

Assembly of Led Module

workshop of led display manufacturer

workshop

Back-Reflow machine

Finished screen 72 hours testing

Aging testing for finished screen

Cabinet assembly

Full screen testing

screw fixing machine

module assembly

SMT machine

SMT production line

SMT equipment

Tin-brush machine

full cabinet testing

full screen testing

glue drying shelf

High temprature testing room

Led board processing

Led board processing

Cutting-pin machine

Cutting-pin machine

Production line in a row

testing

testing

glue filling

cabinet testing

|

workshop of led display manufacturer Tin base design in PCB board is very crucial for SMT procedure. Our engineers are well-known in doing this design. Of course, the imported SMT machine from Japan can do better tin-brush job. |

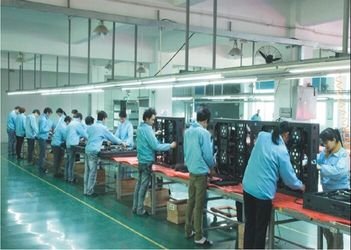

Assembly of Led Module Skilled workers do module assemblying job while wearing anti-electric ring. |

workshop of led display manufacturer All machines are in a row, that looks very neat in workshop. |

workshop Through glass you can see inside of our workshop |

Back-Reflow machine after tin-brushed on PCB board, nine zone back-Reflow machine Heats Leds on PCB board while other factories only have 4 zone back-reflow machine. |

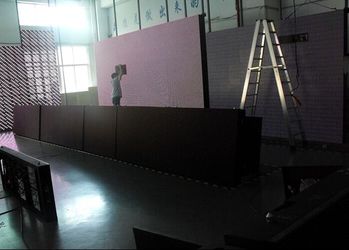

Finished screen 72 hours testing After full cabinet testing, we will Test whole screen for 72 hrs before delivery, so that our clients can get perfect led display or led screen |

Aging testing for finished screen Aging testing finished led display for 3 days |

Cabinet assembly workers attach power supplies, cables, fans, etc, inside cabient. |

Full screen testing 72 hoursTesting finished screen before delivery |

screw fixing machine we use machine to fix pcb on module frame |

module assembly Testing PCB board and doing assembly |

SMT machine this machine is for put Leds on PCB board |

SMT production line doing SMT |

SMT equipment This for making working lighting PCB board |

Tin-brush machine Machine for brushing tin on PCB board |

full cabinet testing after assembling parts on cabinet, we will test whole cabinet to check whether there is crucial problems. |

full screen testing 72 hours testing for whole screen |

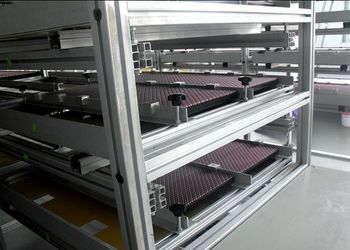

glue drying shelf after glue filling on module, we put it on shelf to cool and dry the sillicon |

High temprature testing room High temprature testing room for testing all cabinets in sure our led displays work well under extrem outdoor enviroment |

Led board processing Led board processing for DIP module |

Led board processing Led board processing for DIP module |

Cutting-pin machine Pin-cutting machine as well as first testing of Leds |

Cutting-pin machine Pin-cutting machine as well as first testing of Leds |

Production line in a row Neat production lines ensure best products production |

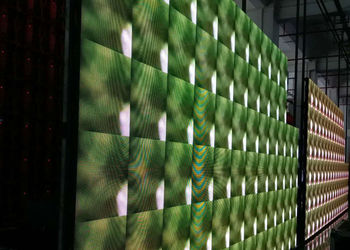

testing testing for full transparent led display |

testing testing for full transparent led display |

glue filling machine for filling silling glue in module frame |

cabinet testing cabinet testing to check small problems after assembling |

![]()

Contact Person: Jason

Tel: +86 136 8684 0889

Fax: 86-755-2905-8213